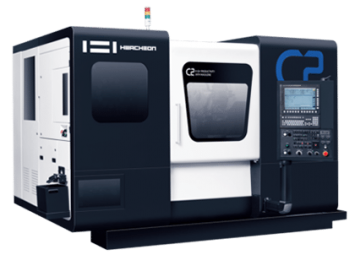

Dual-spindle multi-functional horizontal turning center

- Ladder designed guide rail type machine bed, horizontal spindle headstock with spindle motor in vertical layout

- Dual-spindle (main spindle sleeve, sub-spindle motorized) fast response and high precision, machine both sides in one procedure.

- Y-axis equipped with driven turret, designed for four-axis linkage turning and milling compound processing

Broad application in below prospects: Automated production lines, complex parts processing, efficient batch production, multi-variety small batch production and precision processing.

Specifications

| X/Y/Z/B axis travel | 240/±50 /555/550mm |

| Max. turning length | 550mm |

| Max. swing over bed | Ф610mm |

| X/Z axis positioning accuracy | 0.008 |

| Max. swing over saddle | Ф400mm |

| X/Z re-positioning accuracy | 0.004 |

| Max. turning diameter | Ф400mm |

| X/Y/Z Rapid feed speed | 24/10/30m/min |

| Max. spindle speed | Main spindle 4500rpm, Sub-spindle 5000rpm |

| Rapid feed speed of B axis | Sub-spindle 30m/min |

| Spindle power | Main spindle 11/15kW, Sub-spindle 7.5/11kW |

| Max. torque | Main spindle 286.5N.m, Sub-spindle 82.1N.m |

| Spindle nose | A2-6 (Sleeve spindle) |

| Sub-spindle | A2-5 (motorized spindle) |

| Spindle hole diameter | Main spindle chuck: Hydraulic hollow Φ66mm |

| Spindle hole diameter | Sub-spindle chuck: Hydraulic hollow Φ56mm |

| Chuck diameter | Main spindle chuck 8, Sub-spindle chuck 6 |

| Turret capacity | 12T-driven turret (with Y axis) |

| Tool rotation time | 0.8S |

| CNC system | FANUC 0i TF Plus |