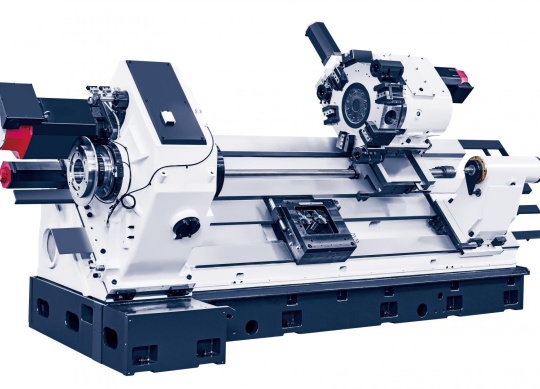

Hi-Tech 700 has a integrated 45-degree slant bed frame to minimize heat distortion, all guide ways are designed as solid box guide ways to maintain rigidity and precision, even during prolonged operations.

Specifications

| Swing Over Bed | Ø900mm |

| Max. Cutting Diameter | Ø680mm |

| Max. Cutting Length | 1986mm |

| Chuck Size | 15" |

| Max. Spindle Speed | 1800rpm |

| Through Spindle Hole Diameter | Ø132mm |

| Spindle Motor | 37kW |

| Rapid Speed (X/Z) | 18/18m/min |

| Max. Stroke (X/Z) | 360/2050mm |

Product Description

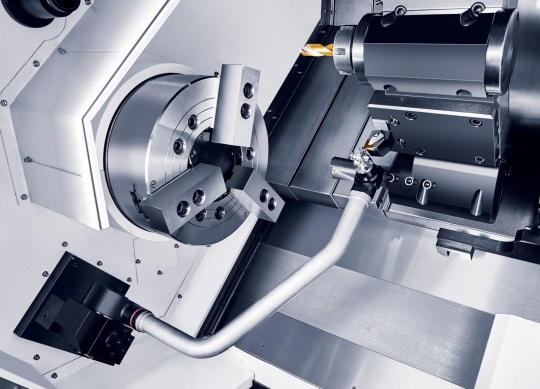

Highly rigid spindle design

The ultra-precision recuperative cylindrical roller bearing and the multiple thrust angular bearing have been incorporated for hard turning of extra solid subjects. The spindle may be geared down for extra torque, to process a wide range of materials.

- At low gear: 0-450rpm

- At high gear: 0-1,800rpm

- Max torque: 3,071Nm(@ 115rpm)

Advanced thermal displacement control

- High-precision hard turning spindle: 37/30kW, 45/37kW

- 15-inch, 18-inch, 21-inch, 24-inch chuck sizes

- Rapid feed (X/Z): 18/18 m/min

- Highly rigid 150 mm diameter tailstock (MT#5)

- Large work area; Longest workpiece 2 m

- Jet lubrication spindle bearing cooling system

Highly rigid spindle design

The ultra-precision recuperative cylindrical roller bearing and the multiple thrust angular bearing have been incorporated for hard turning of extra solid subjects. The spindle may be geared down for extra torque, to process a wide range of materials.

- At low gear: 0-450rpm

- At high gear: 0-1,800rpm

- Max torque: 3,071Nm(@115rpm)

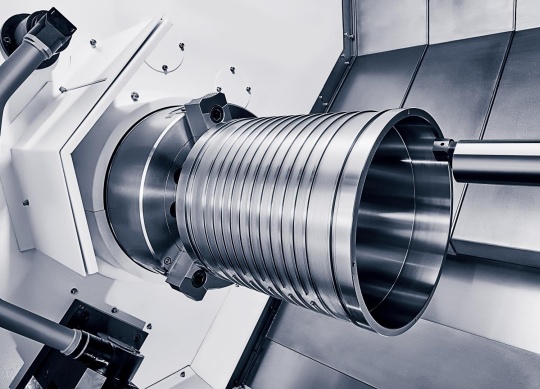

Advanced thermal displacement control

Hwacheon's advanced, patented design prevents deterioration of the workpiece from thermal displacement. The jet of lubrication is constantly applied to the spindle bearing for lubrication and cooling, to increase the machine's life and the precision in machining.

Tailstock

Hi-TECH 700 integrates a system which houses bearings in its tailstock, to guarantee the high degree of precision even after the machine's prolonged heavy-duty turning on a large, heavy workpiece.

- Quill diameter: Ø150mm

- Quill stroke: 150mm

- Quill travel: 1878mm

- Quill taper: MT5

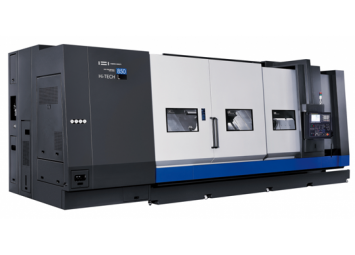

The "Manual Guide I" functionality

Manual Guide I is a dialog-based programming system. Even a beginner can write an advanced program by following simple dialogs and menus; and the data can easily transform into a 3D model, providing the operator with the preview of what actual outcome will look like. This is an excellent system which can improve your productivity and efficiency.