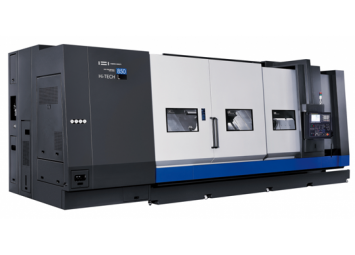

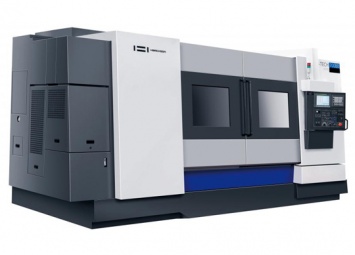

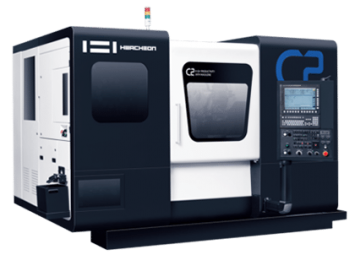

High performance mid-size 15"-18" horizontal turning center

Hi-TECH 550 is equipped with the extra rigid tool post of highest durability to deliver the most stable, precision machining performance even at hard turning.

Specifications

| Swing Over Bed | Ø800mm |

| Max. Cutting Diameter | Ø590mm |

| Max. Cutting Length (L, XL) | 1100mm(2100,3200mm) |

| Chuck Size (A/B) | 381/457mm |

| Max. Spindle Speed (A/B) | 2000/1800rpm |

| Bar Capacity | Ø116mm |

| Spindle Motor Power | 30/22kW |

| Tool Storage Capacity | 12 |

Product Description

- High-performance spindle with wide-range power output: 30/22kW

- 15-inch and 18-inch chuck sizes

- Turret indexing time(1 face): 0.2 s

- Highly rigid 120 mm diameter tailstock (MT#5)

- Direct-coupled servo motor for high-precision machining with no backlashes

HEAVY DUTY CUTTING WITH BOX WAY & GEAR BOX TYPE

Hwacheon's Hi-TECH 550 incorporates tough box way design which makes it an ideal turning center for heavy duty hard turning . It's equipped with a long bed for extra-length workpieces, and with the programmable tailstock and steady rest for stability and precision. Machining precision is enhanced even further because all of the Hi-TECH 550's axes can be installed with highly accurate linear scales; and the fast turret indexing time of 0.2 seconds per step will increase your productivity.

Tough, Rapid Indexing Turret

The turret in Hi-TECH 550 with a powerful clamping force offers an index time of 0.2seclstep for faster, more stable machining.

Programmable Tailstock (Standard)

The tailstock can be programmed to position itself in semi-auto, and it provides firm support for extra-long workpieces to guarantee machining precision. The tail spindle can be operated either by the foot switch or by programming, while providing firm, stable oilpressure chucking.

Steady Rest (Option)

Add the Steady rest when working with extra-long workpieces to raise machining precision.

USER FRIENDLY DESIGN, A WIDE RANGE OF OPTIONAL FEATURES

Hi-TECH 550 is designed to be user friendly, so you can concentrate on what you do best: creating quality products-without losing your valuable time to the worries of machine failure and safety. A wide variety of performance upgrade options are available for faster, more precise machining.