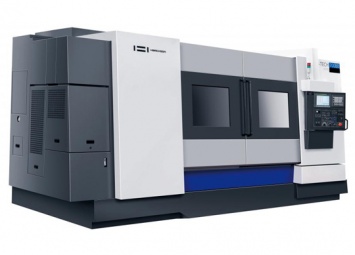

- High accuracy

- Utmost convenience

- Heavy duty cutting

- High stability

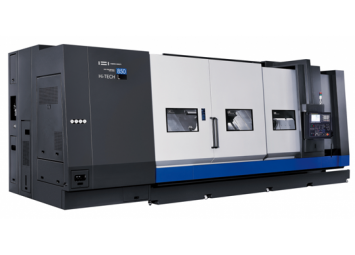

- Four bed sizes: 3,4,5 and 6 meters turning length

Specifications

| Swing of bed | Ø1080mm |

| Swing of cross slide | Ø720mm |

| Max. cutting diameter of bed | Ø1000mm |

| Distance between centers | 3000-6000mm |

| Spindle nose | A2-15 |

| Spindle power motor | 18.5/23kW |

Product Description

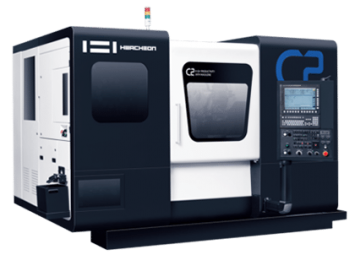

HIGH ACCURACY

- Adoption of ball screw and servo motor

- Easy checking for spindle speeds by attachment of spindle position encoder

- Guarantee of repeatability ±5° by adoption of curvic toolpost

UTMOST CONVENIENCE

- Excellent operation & easy loading/ unloading work piece by convenient operation panel

- Semiautomatic tailstock feeding device

HEAVY DUTY CUTTING

- Heavy duty cutting and precision turning by one piece fabricated bed & leg structure

- High rigid headstock:

-- Spindle through hole ∅155 mm : four point contacts with ball bearing, cylindrical roller bearing, angular bearing

-- Spindle through hole ∅255 mm : three point contacts with taper roller bearing

--Spindle through hole ∅320 mm : three point contacts with taper roller bearing, double roller bearing

- Ball screw

--X-axis: ∅32 x 6 mm

--Z-axis: ∅50 x 12 mm (3000T/4000T), ∅62 x 12 mm (5000T),

- ∅80 x 12 mm (6000T)

- Guide way : Turcite

HIGH STABILITY

- Maintaining high accuracy by turcite laminated on slide surfaces

- Application of high pressure lubrication pump to guarantee perfect lubrication on slide surfaces

- Prevention of operation error by lock type mono lever switch (Opt. Fixed MPG handle)