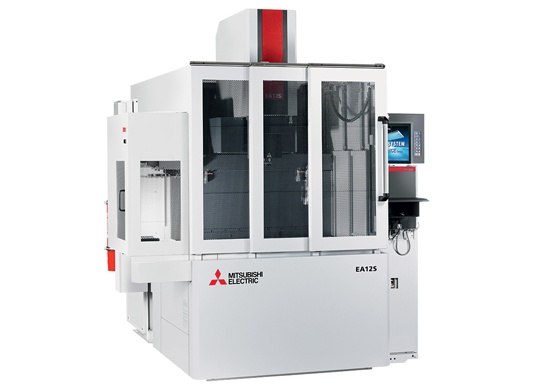

The Mitsubishi EA12S Advance features the new M700 series control with 15” touch screen and FP80S energy saving power supply, reducing electrical consumption by 20% as compared to the previous FP model. The all new Power Master GF2 Adaptive Control reduces graphite electrode wear by as much as 80%. The addition of the new SS Jump 5 optimizes jump up acceleration control to stabilize high speed No-Flush burning.

Specifications

| Machine Travels X x Y x Z | 400 x 300 x 300mm |

| Max Dielectric Fluid Level | 79 ~ 400mm |

| Power Supply (Option) / Peak Current | 80 |

| Internal Worktank Dimensions W x D x H | 900 x 700 x 450mm |

| Max. Workpiece Weight | 998kg |

| Table Dimensions W x D | 702 x 500mm |

| Max. Electrode Weight | 50kg |

| Machine System Weight | 3500kg |

| C-Axis Min. Indexing Angle / Drive Unit | 0.001 ̊/ 0.001 ̊ |

| C-Axis RPM Range | 1 to 30 |

| Fluid Temp. Control | Chiller |

| Table to Platen Distance | 201 - 500mm |

| Machine Unit Dimensions W x D x H | 1725 x 2132 x 2400mm |

| Control Unit Graphic Display Function | 15" TFT color LCD |

| Control Unit CPU/type | 64-bit / PC |

Product Description

- FP80S Power Supply Provides 80 Peak AMPs

- Compact Highly-Rigid Machine Design

- Fixed Table Traveling Column Construction

- Direct Drive AC Smart Servo System

- 3 Dimensional Lateral Servo System

- M700 Series Control w 15” Touch Screen

- 40GB HD with a 1GB partition for user program storage

- 3-Sided Drop Tank Work Tank Access

- Power Master (GF2 Adaptive Control)

- Fine Finishing with the PS Circuit Standard

- Easy Access Filter System

- Dielectric Fluid Emission

- Auto Lubrication System

- E.S.P.E.R. Advance Program Support Functions

- Fuzzy Pro Plus Hands Off Operation

- Full 2-yr. Warranty with Triple Diamond Partnership Program