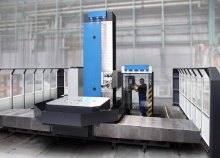

Mitsubishi MP1200 & MP2400 WEDM

Image

Machining Accuracy

Next-generation drive system and optimum machine structure

Machining Accuracy

Next-generation drive system and optimum machine structure

Optical Drive System

- High-speed fiber-optic communications and a linear shaft motor synergistically improve machining accuracy

- A servo amplifier and control unit developed by Mitsubishi Electric contribute to system optimization