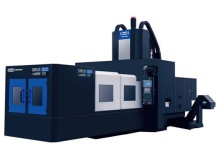

Zopo VMC850P Vertical Machining Center

Machine structure

-The contact ratio between spindle case and column increased to ensure spindle rigidity.

-1100mm wide machine body span and optimum supporting design can meet with fast feed of X and Y axis.

-Big size of “pyramid” column and with closed inner cavity to ensure low center but high rigidity support of Z axis.

Preloaded and double anchored ball screw