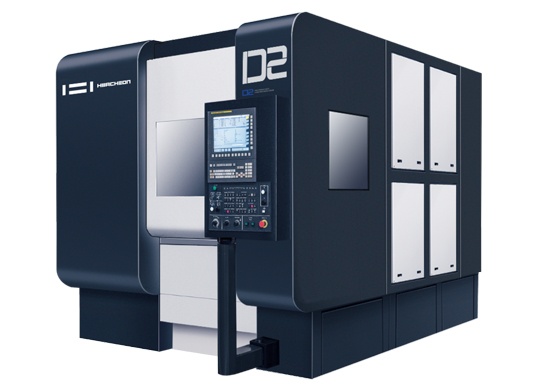

Compact 5-Axis Machining Center

For General Parts Or Most Complex Shapes & Contour Applications

Hwacheon’s newest design for 4+1 or simultaneous 5-axis applications offers a cost-effective solution to a very wide range of applications and materials. Highest precision, highest flexibility or automated production – the D2-5AX is your solution.

Specifications

| Axis Stroke (X/Y/Z) [mm] |

650 / 500 / 500 |

|---|---|

| Working Surface [mm] |

Ø600 |

| Max. Table Load [kg] |

500 |

| Max. Spindle Speed [rpm] |

12 000 (opt. 14 000 / 20 000 / 24 000) |

| Spindle Power [kW] |

37 / 18.5 (opt. 37 / 22, 37 / 18,5, 37 / 18.5) |

| Type of Spindle |

BBT-40 (opt. CAT-40 / SK-40 / HSK-A63) |

| Rapid Speed (X/Y/Z) [m/min] |

30 / 30 / 30 |

| Rapid Speed (B/C) [rpm] |

25 / 25 |

| Tool Storage Capacity [ea] |

30 (opt. 40 / 60) |

| Floor Space (L x W) |

3 700 x 3 523 (with chip conveyor) |

| CNC System |

Fanuc Oi-MF ( opt. Fanuc 31i-B5) |

Product Description

Product Description

High productivity 5 Axis machining center

Compact 5-axis machining center for part or most complex contour applications. Cycle times are kept at its lowest due to high acceleration/deceleration times as well as short tool change times. The design considers easy access for AWC or robot handling.

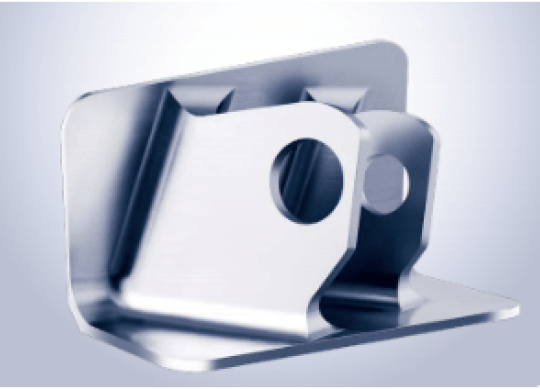

High-performance spindle

Four (4) different built-in motor spindles can be selected to guarantee optimum cutting conditions. From high speed to high torque, suitable from aluminum to titanium or stainless steel, this machine provides the best machine configuration. Comes standard with BBT-40.

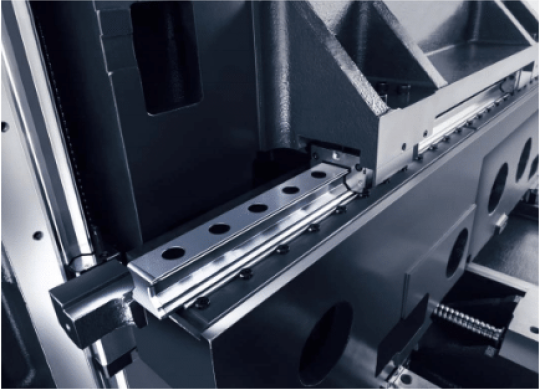

High precision table

The 2-axis rotary/swivel table with cantilever support can handle parts up to 500 kg, precisely positioned or synchronized operating. Chip discharge is safe and fast through designed chip flow. Easy access to the table is provided by an auto ceiling opening/closing latch.

Hwacheon Software

The machine comes standard with Hwacheon Software package to optimize operations and ensure constant temperature control.

The customer can select the HRCC option (Hwacheon Rotation Center Calibration System) which include a touch probe and specific software to calibrate all 5-axis quickly and accurately.

M-Vision Plus can be selected to monitor machine state in real time – any time by smartphone, computer or desktop.