LEAD MACHINE TOOLS INSTALLS SINO VMC1000L IN CAPE TOWN

In June 2019 Lead Machine Tools installed a Sino VMC1000L Vertical Machining Center.

SINO VMC1000L SPECIFICATIONS

In June 2019 Lead Machine Tools installed a Sino VMC1000L Vertical Machining Center.

SINO VMC1000L SPECIFICATIONS

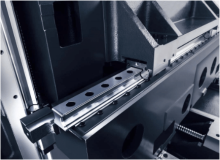

High Rigid & Large Horizontal Machining Center

Powerful Spindle

Various Functions

High-performance Spindle

The spindle integrated motor limits vibration, noise and power loss at high speed operations. The oil-jet system injects directly into the spindle bearing for effective lubrication and cooling, the motor and the spindle assembly are jacket-cooled to limit the displacement caused by heat. To achieve greater precision, the spindle constantly monitors for thermal displacement and makes necessary adjustment in real time.

Product Description

Machining Solution With Hwacheon Software

High-Precision And High-Rigidity Index Table: Application of dedicated index table optimized for slide/incline core machining

Product Description

Machining Solution With Hwacheon Software

High-Precision And High-Rigidity Index Table: Application of dedicated index table optimized for slide/incline core machining

Intuitive Operating Environment

- Automatic attachment of table and clamping jig

- Intuitive angle input for B/C axes

- Automatic creation of 3+2-axis post based on input angles

- Automatic linkage of machining command function for inclined surfaces

Stable, Symmetrical Portal-Type Structure

Stable, Symmetrical Portal-Type Structure

The double columns provide stable support for the Y-axis feed system, and the symmetrical structure that distributes the load, vibration, and heat of the upper area throughout the entire frame enables stable feed even during prolonged operation. Also, minimizing the distance between the Y-axis feed system and the tool's machining point maintains rigidity and increases machining precision.

Direct Drive Type Rotation Axis

High productivity 5 Axis machining center

High productivity 5 Axis machining center

Compact 5-axis machining center for part or most complex contour applications. Cycle times are kept at its lowest due to high acceleration/deceleration times as well as short tool change times. The design considers easy access for AWC or robot handling.

High-performance spindle

We just completed the installation of this world class Microdynamics Mega 30VT at Drill Mech in Johannesburg! For more information on this machine click here... http://www.leadmachinetools.co.za/product/mega-30vt

Micro Dynamics is a world class Machine Tool Manufacturer based in the USA. Their machines are the epitome of power, speed and accuracy all rolled into a one world class product. Micro Dynamics machines feature the ISO40 built-in Spindle for monster power and high speed, not to mention superb accuracy; 0.005mm Thermal Stability Throughout, 0.1μm Ultra High Resolution.

Lead Machine Tools visited Sino at the Beijing Machine Tool show in China!

Another great installation in Cape Town of a Sino VMC-850 with Siemens 828D at Alba Engineering. A big thank you to Derek Howitt for your support!

Alba Precision Manufacturing is a precision CNC Production Engineering company, formed in 2009, and is based in Retreat, Cape Town. We specialise in CNC turning and CNC milling. The company is focused on small, medium, and large batch production components in stainless steel, steel, aluminium, brass and various other materials. We are capable of complex solid, 3D, and 2D milling utilising our Edgecam CADCAM software.