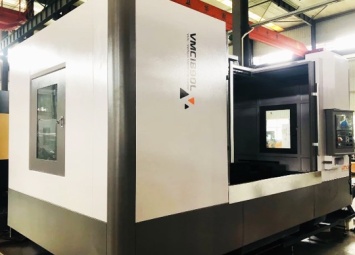

SVB1270 High Rigidity Good Accuracy Large Vertical Machining Center

SVB series is the newly designed series of machine SINO cooperated together with Taiwan company. The design concept, assembly know how and inspection method all follow Taiwan machine standard.

Product Description

Machine structure

- Pagoda type structure design and reinforcing ribs inside to ensure rigidity.

- Enclosed box type headstock with front end circular design to reduce weight compared with square design also the load of Z axis and the forward leaning phenomenon.

- X/Z axis large 45/55mm roller linear guideway with 6 slides , Y axis has 4x45mm roller linear guideways with 8 sliders.

Intergrated ball screw housing and double nut ball screw

- Servo motor directly coupled ball screw.

- Intergrated ball screw housing improves rigidity and stability.Directly coupled servo motor eliminates any factors which will influence accuracy and efficiency.

- All the ball screws, linear guideway, bearings are well lubricated in time and ration.

- 3 axes double nut ball screw (5012) with 4+3 bearings (4072)

Shoulder carrying tool magazine

Shoulder carrying tool magazine can ensure Z axis geometric accuracy and perfect stability, rigidity and the minimum deformation when column loaded with tool magazine weight.

Chip conveyor and chip flushing

- Double screw chip conveyor at two sides of machine inside which improves chip moving efficiency.Standard equipped with inner -- Side flushing system to remove scraps efficiently.

Short nose spindle

- Short nose spindle front 3 rear 2 bearings, direct driven and gear transimission spindle is optional

Contact us

Specifications

| Worktable size | 1600x700mm |

| Max. load capacity | 1100kg |

| X-Axis travel | 1400mm |

| Y-Axis travel | 700mm |

| Z-Axis travel | 700mm |

| Spindle nose taper | BT50 |

| Spindle speed (pulley) | 6000rpm |

| Rapid traverse rate | 24/24/20m/min |

| Number of tool | 24 |