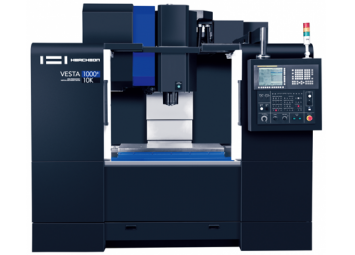

Hard Machining Results Every Time VESTA-850B is the answer.

Hwacheon's vertical machining center employ highly tough, highly rigid box way design on all axes for ultimate precision . These machines can be configured with a wide choice of spindle models to satisfy your production needs.

Specifications

| Stroke (X/Y/Z) | 850/600/600mm |

| Feedrate Rapid Speed (X/Y/Z) | 24/24/18m/min |

| Table Size (Width x Length) | 1050x600mm |

| Table Loading Capacity | 800kg |

| Max. Spindle Speed | 8000rpm (6000rpm) |

| Spindle Motor Power | 11/7.5kW (18.5/15kW |

| Type of Tool Shank | BT-40 (Opt. CAT-40)/BT-50 (Opt. CAT-50) |

| Tool Storage Capacity | 24 (Opt. 30) |

| Floor Space (Length X Width) | 3640x2185mm |

Product Description

- 8000rpm or 6000rpm high-speed spindles to choose from

- Feed(X/Y/Z): 850/600/600mm

- Gear-driven high-torque spindle: 2-speed shifting

- Box way design for all axes

PRECISION HEAVY-DUTY MACHINING

In heavy duty cutting, stability is the key

Everything about VESTA-850B is detail. These machining centers don't miss even the smallest detail to ensure top performance.

Built with Hwacheon's advanced technology and craftsmanship, VESTA-850B is the class-leading vertical machining center that will guarantee to give you the quality you seek for your manufacture requirements. The 850B's feed drive employs all-axis box way design for precision and performance; while the structure is 3D FEM analyzed to make it tough yet efficient.

Built-Out Spindle

Hwacheon's spindles are the best in the class. The high-performance spindle incorporated is motor-integrated for stability and precision at high speed; and the temperature around the spindle assembly is efficiently regulated with Hwacheon's unique oil-jet lubrication system, to limit heat distortion.

Spindle Cooling System

The motor bearings are lubricated with the semi-permanent grease, and the coolant travels around the motor housing jacket.

Air-Oil Cooling System

Hwacheon's unique air-oil cooling technology, combined with conventional jacket cooling, limits heat distortion even after the machinie is used for prolongedoperation.

Gear Driven Spindle

The 2-speed auto-shifting gear spindle delivers high torque cutting performance at extra low speeds; while providing excellent performance at high speeds.

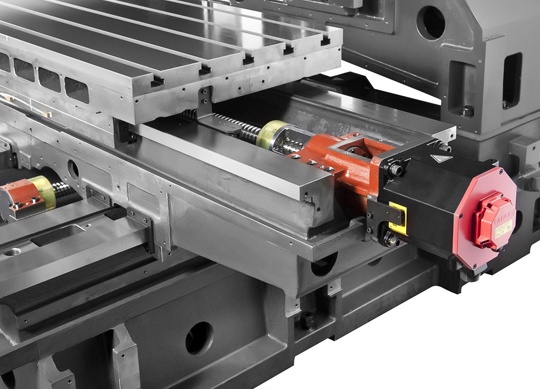

4-Guide Box Way

To limit friction and to increase accurate table feed, the 4-guide box way has been incorporated to the axes. The Y-axis slide way has been widened to enhance the bearing capacity and decrease the area of friction.

Fast Chip Removal Performance

The chip removal system in VESTA series of machining centers are designed with a wide-angle sliding cover and the chip flushing nozzles on each side of the table; and the coil conveyor in front removes the chips quickly and effectively, to make your work more efficient.

Index Table (Option)

Hwacheon's index table can be operated with ease without the need for an additional 4-axis interface, and its 4.3 tons of clamping force and 5 degrees of division angle are ideal for hard turning.

Precision Scraping

Each scraper has been manufactured to perfection with Hwacheon's 60-year workmanship. The scraper helps to absorb vibration during hard turning and to provide fine feed, and to ensure highly precise machining results.

USER FRIENDLY DESIGN, A WIDE RANGE OF OPTIONAL FEATURES

The VESTA-850B system offers a user friendly design and a wide variety of upgrade options for a faster, more precise machining performance, so you can concentrate on what you do best: creating quality products.