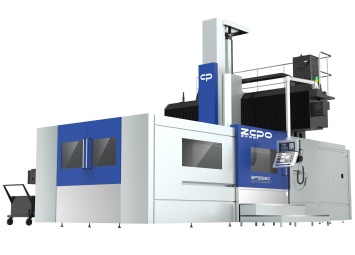

SIRIUS-2500 are large bridge-type vertical machining centers with precision feed drive and high-performance spindle. These machining centers provide a total solution from tool selection to product completion-making them ideal for your extra-size mold applications where quality is essential.

- 8,000 rpm or 12,000 rpm high-speed spindles to choose from

- Oil-jet cooled motor-integrated spindle (30/25 kW) (built-in motor spindle)

- Stroke (X/Y/Z): 3,100 (4,000) / 2,300 / 900 mm

- X axis: Roller LM Guide; Y and Z axes: box way (standard)

- Bilateral gate structure for rigid machine structure

Specifications

| Stroke (X / Y / Z) [mm] | 3100 (4000) / 2300 / 900 |

| Feedrate Rapid Speed (X / Y / Z) [m/min] | 16 (10) / 16 / 16 |

| Table Size (Width x Length) [mm] | 3300 (4200) x 2000 |

| Table Loading Capacity [kg] | 10000 / 15000 |

| Max. Spindle Speed [rpm] | 8000 / 12000 |

| Spindle Motor [kVA] | 30 / 25 |

| Type of Tool Shank | BBT-50 (Opt. CAT-50) |

| Tool Storage Capacity [Amount] | 40 |

| Floor Space (Length X Width) [mm] | 8830 x 5000 |

| NC System | Fanuc 31i-B |

Product Description

Large size mold machining

Hwacheon's extra-size bridge type vertical machining centers guarantee to enhance the quality of your large mold applications, such as large display frames, automotive and aerospace parts and molds. The SIRIUS series of large size vertical machining centers use powerful built-in motor spindles, high precision milling heads complemented by Hwacheon's proprietary Oil-Jet cooling system-to guarantee consistent strong roughing performance and provide high quality product result hours after hours of high speed machining. Each SIRIUS vertical center is designed using 3D simulation FEM analysis to achieve structural rigidity which can translate to quality product results; while the Hwacheon designed machining software components enhance safety and work efficiency in your factory. The machines are configurable with many different options so that they can integrate perfectly to your work environment and application.

Machining Software

Hwacheon's developed machining software monitors different variables related to the work environment and machining conditions, automatically perform adjustments for best quality results and optimum work efficiency.

User friendly design, wide range of options

SIRIUS-2500 vertical machining centers offer user friendly design and a wide variety of useful options for practical applications, so you can concentrate on what you do best: creating quality products-without losing your valuable time to the worries of machine failure and safety. A wide variety of performance enhancing options are available for faster, more precise machining.